Exactly How Stretch Wrapper Repair Service Functions: A Comprehensive Overview to Keeping Your Tools Useful

Stretch wrapper repair work is vital for keeping the performance and integrity of packaging operations. Technicians usually encounter different concerns that can prevent performance. A methodical approach is important for effective repair services. Understanding common problems and having the right tools can make a significant distinction. In addition, recognizing when to perform preventative upkeep can prolong equipment life. This guide discovers the details of stretch wrapper repair and what it requires to keep machinery in suitable condition.

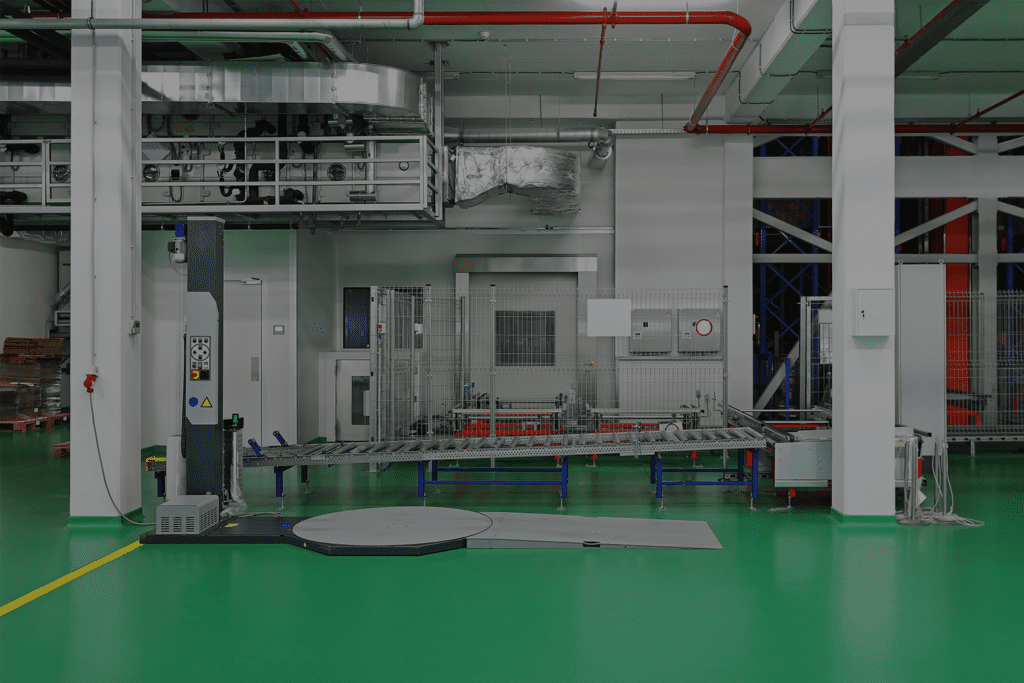

Recognizing Common Stretch Wrapper Issues

As the demand for efficient packaging options raises, comprehending common stretch wrapper issues comes to be crucial for preserving functional effectiveness. Stretch wrappers often run into several common problems that can disrupt workflow. One usual concern is irregular film tension, which can bring about poor lots security. This variance might be due to misaligned settings or worn-out parts. stretch wrapper repair. Additionally, film tearing regularly occurs, leading to thrown away materials and time. Inaccurate filling strategies or improper movie type can add to this problem.Another problem involves the maker's electrical elements, which can malfunction and create operational delays. Routine maintenance is vital to guarantee that electronic systems, such as sensors and electric motors, feature correctly. Finally, mechanical jams might happen, often originating from debris build-up or used gears. Awareness of these problems permits drivers to proactively resolve them, inevitably improving the reliability and effectiveness of stretch covering operations

Tools Needed for Stretch Wrapper Repair Works

Reliable repair services on stretch wrappers call for a particular set of tools customized to resolve the usual issues recognized earlier. Important devices include an outlet and wrench set for loosening up and tightening up screws, which is essential for accessing interior parts. A multimeter is essential for identifying electric problems, enabling professionals to measure voltage and connection in the system. In addition, screwdrivers of various dimensions are important for getting rid of panels and accessing parts that might require replacement or adjustment.A tape action aids ensure exact alignment throughout repairs, while pliers can aid in gripping and adjusting smaller sized elements. Lubricating substances and cleaning up representatives are also crucial for preserving smooth procedure and stopping wear. Safety gear such as handwear covers and goggles must be consisted of to secure the service technician during the repair work process. By equipping themselves with these devices, service technicians can efficiently attend to a variety of issues that may occur in stretch wrappers.

Step-by-Step Fixing Process

Begin the repair service process by guaranteeing the stretch wrapper is powered off and disconnected from the electrical supply. Next off, inspect the device for visible indications of damages or wear, focusing on vital components such as the movie carriage, rollers, and sensors. Remove them meticulously using appropriate tools.Document the disassembly procedure to assist in reassembly if any kind of components appear damaged. Change damaged parts with OEM components to preserve efficiency criteria. After installing new components, reassemble the equipment, making certain all connections are safe and lined up properly.Once rebuilded, perform a thorough inspection of all arrangements and settings - stretch wrapper repair. Power the machine back on and run a test cycle to verify performance. Focus on any type of uncommon sounds or breakdowns during operation. If essential, make additional changes or consult the producer's manual for troubleshooting. Properly document the repair procedure for future reference

Preventative Maintenance Methods

Applying preventative upkeep methods is vital for prolonging the life-span of a stretch wrapper and making sure peak efficiency. Routine assessments need to be conducted to determine any signs of wear or damage, concentrating on crucial parts such as belts, sensors, and electric motors. Cleaning up the equipment consistently helps protect against particles accumulation, which can hamper operation. Lubing relocating parts based on the maker's standards reduces rubbing and extends the life of mechanical elements.Furthermore, keeping appropriate tension on the movie and making sure that the movie rolls are saved correctly reduces strain on the devices. Operators must be trained to identify unusual audios or movements during procedure, as these can indicate possible issues prior to they escalate. Developing an upkeep routine that consists of replacing used parts proactively can greatly reduce the risk of unexpected failures. By adhering to these strategies, services can enhance the dependability and efficiency of their stretch wrappers.

Fixing Tips for Quick Fixes

In resolving usual stretch wrapper concerns, quick repair service techniques play an important duty in reducing downtime. By recognizing the normal issues that occur, operators can carry out reliable maintenance best techniques. This area will certainly check out useful solutions for quick troubleshooting.

Common Stretch Wrapper Issues

Quick Repair Service Techniques

Upkeep Ideal Practices

While regular maintenance is important for suitable efficiency, executing finest techniques for troubleshooting can likewise lead to fast fixes. Determining and addressing typical problems promptly is vital. Operators must acquaint themselves with the stretch wrapper's manual, as it commonly consists of useful fixing tips. Frequently inspecting parts like rollers, belts, and electrical connections can protect against minor problems from intensifying. Maintaining a log of persisting concerns helps pinpoint patterns and options. In addition, keeping a clean workspace reduces the danger of particles affecting devices capability. When coming across a mistake, rebooting the maker can solve numerous short-term problems. Making use of manufacturer resources and on-line forums a knockout post can likewise offer fast understandings from seasoned customers, guaranteeing that equipment remains operational with very little downtime.

When to Call a Professional Service Technician

When should one consider reaching out to an expert specialist for stretch wrapper repairs? Normally, a specialist must be called when the tools experiences persistent concerns that can not be settled through fundamental troubleshooting. If the stretch wrapper regularly stops working to run, presents mistake codes, or if components such as the electric motor or control panel show indicators of damages, specialist aid is called for. In addition, if the equipment needs specialized devices or knowledge for repair, employing a technician ensures a correct resolution.Moreover, when the repair tries lead to more complex issues or when downtime influences manufacturing schedules considerably, expert treatment might be needed. Normal maintenance checks can assist in recognizing possible issues early, but once a malfunction happens that goes beyond the operator's capability, it is sensible to hire a professional. This strategy not only assures efficient repairs however additionally preserves operational performance and security within the work environment.

Best Practices for Devices Longevity

To assure the longevity of stretch wrapping equipment, a normal upkeep schedule is vital. Following proper use techniques likewise plays a crucial duty in lessening wear and tear. Carrying out these best techniques can substantially prolong the life expectancy of the machinery.

Regular Maintenance Schedule

A well-structured routine maintenance timetable is crucial for ensuring look at this website the durability of stretch covering devices. This schedule should include daily, weekly, and month-to-month tasks customized to the details version and use problems. Daily evaluations should concentrate on looking for signs of wear, making sure proper stress, and confirming that safety and security functions are operational. Weekly upkeep can involve cleaning up the equipment and lubricating moving components to minimize rubbing. stretch wrapper repair. Regular monthly evaluations should encompass a complete evaluation of electric components and drive systems. Keeping comprehensive records of upkeep tasks help in recognizing patterns or repeating problems, assisting in prompt interventions. Adhering to this routine not only extends equipment life but additionally boosts performance, minimizing downtime and repair work costs

Correct Usage Methods

Normal upkeep is just one facet of making the most of the lifespan of stretch covering equipment; proper use techniques also play a significant function in boosting efficiency and resilience. Operators ought to be educated sufficiently to ensure they understand the tools's restrictions and functionalities. Continually adhering to the producer's guidelines for tons sizes and wrapping patterns is crucial. In addition, preserving a tidy operating setting assists stop debris accumulation, which can restrain the machine's performance. It is necessary to keep track of the tension settings to stop over-stretching or under-stretching the film, both of which can bring about ineffective wrapping. Validating that the tools is operated within its defined parameters will certainly decrease wear and tear, eventually expanding its operational life and decreasing the need for fixings.

Often Asked Concerns

Exactly how Frequently Should I Execute Regular Maintenance on My Stretch Wrapper?

Routine maintenance on a stretch wrapper need to preferably be carried out every 3 to six months, relying on usage. Routine checks can stop breakdowns and guarantee peak performance, prolonging the maker's lifespan and enhancing operational effectiveness.

What Are the Indications Showing My Stretch Wrapper Requirements Immediate Repair Work?

Indications that a stretch wrapper needs immediate repair include unusual sounds during procedure, inconsistent covering stress, mistake messages on the control board, and visible damage to components, showing prospective failing that calls for punctual focus to avoid further issues.

Can I Use Any Kind Of Lubricating Substance for My Stretch Wrapper Elements?

Utilizing any type of lube on stretch wrapper parts may result in problems. It is crucial to utilize manufacturer-recommended lubricating substances to ensure peak performance and prevent damage, as incompatibility can cause breakdowns and increased maintenance costs.

Exactly how Do I Choose the Right Stretch Wrap for My Maker?

Choosing the ideal stretch wrap entails taking into consideration device specs, tons type, and ecological variables. Evaluating thickness, stretchability, and size warranties perfect efficiency, avoiding damages while keeping product honesty during storage space and transport. Correct option is crucial.

Is It Safe to Operate a Malfunctioning Stretch Wrapper Briefly?

Operating a malfunctioning stretch wrapper, also briefly, presents considerable safety and security dangers. It can result in further devices damage and raise the probability of accidents, jeopardizing both operator security and overall efficiency in the office. As the need for efficient product packaging services boosts, recognizing common stretch wrapper issues comes to be crucial for keeping operational efficiency. Effective repairs on stretch wrappers call for a specific collection of tools customized to attend to the usual issues determined previously. In addressing usual stretch wrapper problems, fast repair strategies play a vital duty in lessening downtime. Attending to these usual stretch wrapper concerns without delay ensures marginal downtime, keeping productivity and performance in packaging operations. Utilizing any lubricating substance on stretch wrapper elements might lead to concerns.